- Home > Products > Ball Valve >

DIN F4 Ball Valve

- Model:

- -

- Size:

- DN50-DN300

- Pressure:

- PN10,PN16

- Body Materials:

- GG25, Ductile Iron GGG40, GGG50

- Applicable Medium:

- Water etc.

- Send us Email

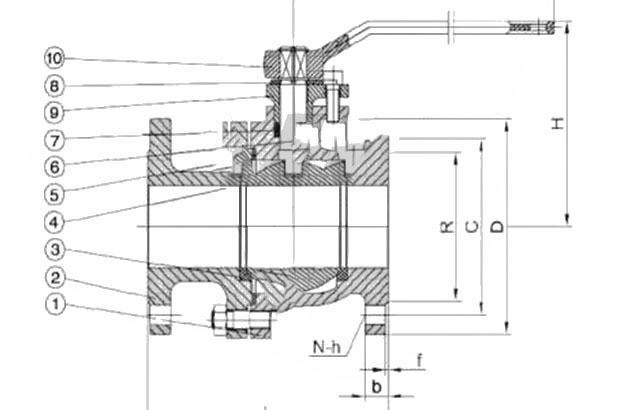

Product Introduction

The high platform ball valve and flange gate valve belong to the same type of valve. The difference is that its closing part is a sphere. The sphere rotates around the center line of the valve body to open and close the valve. Ball valves are mainly used in piping to cut off, distribute and change the flow direction of media. Two-piece ball valve and three-piece ball valve are widely used as a new type of valve.

Body Material: GG25, Ductile Iron GGG40, GGG50

Bonnet Materials: GG25, Ductile Iron GGG40, GGG50

Ball: SS420/SS304

Seat: PTFE

Stem: SS420/SS304

End Connection: Flanged

Product Features

1. Keep the position of the valve handle rotating.

2. Cannot be used as a throttle.

The ball valve of belt drive mechanism should be installed upright.

The working principle of the high platform ball valve is to rely on the love of the rotary valve to make the valve unblocked or blocked. Ball valve switch is light, small, can be made into a large caliber, reliable seal, simple structure, easy maintenance, sealing surface and sphere are often in closed state, not easy to be eroded by media, widely used in various industries.

The high platform ball valve is mainly used to cut off, distribute and change the flow direction of the medium in the pipeline. Ball valve is a new type of valve widely used in recent years.

Technical Parameters

| Norminal diameter | L | H | W | D2 | D1 | D | b | n-b |

| 15 | 115 | 78 | 130 | 45 | 65 | 95 | 14 | 4-014 |

| 20 | 120 | 113 | 160 | 58 | 75 | 105 | 16 | 4-4)14 |

| 25 | 125 | 107 | 160 | 68 | 85 | 115 | 16 | 4-4)14 |

| 32 | 130 | 113 | 160 | 78 | 105 | 140 | 18 | 4-4)18 |

| 40 | 140 | 130 | 250 | 88 | 110 | 150 | 18 | 4-4)18 |

| 50 | 150 | 146 | 250 | 102 | 125 | 165 | 20 | 4-4)18 |

| 65 | 170 | 176 | 350 | 122 | 145 | 185 | 20 | 4-4)18 |

| 80 | 180 | 222 | 350 | 138 | 160 | 200 | 22 | 8-4)18 |

| 100 | 190 | 222 | 400 | 158 | 180 | 220 | 24 | 8-4)18 |

| 125 | 325 | 257 | 750 | 188 | 210 | 250 | 26 | 8-4)18 |

| 150 | 350 | 275 | 850 | 212 | 240 | 285 | 28 | 8-4)23 |

| 200 | 400 | 400 | 1200 | 268 | 295 | 340 | 30 | 12-4)23 |

Technical Standard

1.Design and manufacture according to DIN3357

2. Face to face according to DIN3202

3.Flange drilling according to DIN2533

4.Pressure test according to DIN3230